Request an online quote today.

All Uploads are Secure and Confidential

All Uploads are Secure and ConfidentialCertifications:

ISO 13485 | IATF 16949

Nylon

PETG

ABS

PLA

Durable and flexible, great for end-use parts.

Combines strength and flexibility, perfect for mechanical components.

Strong and heat-resistant, suitable for functional parts.

Biodegradable and easy to print, ideal for prototypes.

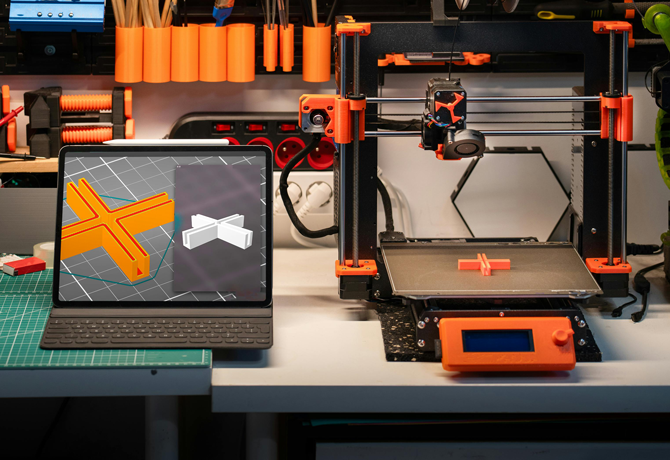

What is 3D Printing?

What is 3D Printing?

3D printing is a technology that manufactures objects by stacking materials layer by layer, also known as additive manufacturing. It starts from digital design files (such as STL format) and uses various materials (like plastics, metals, resins, etc.) to print complex shapes and structures that traditional methods cannot easily achieve.

What materials can be used in 3D printing?

What materials can be used in 3D printing?

Common 3D printing materials include:

The choice of material typically depends on the application requirements, durability, cost, and processing precision of the printed item.

What are the differences between 3D printing and traditional manufacturing methods?

What are the differences between 3D printing and traditional manufacturing methods?

Unlike traditional manufacturing methods (such as casting, cutting, molding, etc.), 3D printing is an additive manufacturing process that constructs objects by layering materials without the need for molds or machining tools. This method can produce very complex structures while reducing waste and processing time. Additionally, 3D printing allows for personalized customization, making it ideal for small batch production and prototype design.

How to ensure the quality of 3D printed models?

How to ensure the quality of 3D printed models?

Key factors for ensuring 3D printing quality include:

What is the precision of 3D printing?

What is the precision of 3D printing?

The precision of 3D printing depends on various factors, including the type of printer used, materials, and printing settings. Generally, FDM (Fused Deposition Modeling) printers have a precision range of 0.1mm to 0.5mm, while SLA (Stereolithography) printers can achieve a precision of around 0.05mm.

What applications are suitable for 3D printing?

What applications are suitable for 3D printing?

3D printing is widely applied in multiple fields, including:

As technology advances, the range of applications for 3D printing continues to expand.

What is the cost of 3D printing?

What is the cost of 3D printing?

The cost of 3D printing varies due to several factors, including:

Generally, 3D printing is suitable for small batch production or personalized customization; for large-scale production, traditional manufacturing methods may be more cost-effective.

How to choose the appropriate 3D printing technology?

How to choose the appropriate 3D printing technology?

Choosing the right 3D printing technology requires consideration of several factors: