Request an online quote today.

All Uploads are Secure and Confidential

All Uploads are Secure and ConfidentialCertifications:

ISO 13485 | IATF 16949

6063

6061

Properties: Lightweight, corrosion-resistant, good thermal and electrical conductivity.

Applications: Aerospace components, automotive parts, structural frames, heat exchangers.

Benefits: Excellent machinability, high strength-to-weight ratio, and availability in various alloys fortailored applications.

Properties: Lightweight, corrosion-resistant, good thermal and electrical conductivity.

Applications: Aerospace components, automotive parts, structural frames, heat exchangers.

Benefits: Excellent machinability, high strength-to-weight ratio, and availability in various alloys fortailored applications.

304

303

420

430

316

Properties: High strength, excellent corrosion resistance, and heat resistance.

Applications: Medical devices, food processing equipment, marine applications, and industrial machinery.

Benefits: Durability, aesthetic appeal, and ability to withstand harsh environments.

Properties: High strength, excellent corrosion resistance, and heat resistance.

Applications: Medical devices, food processing equipment, marine applications, and industrial machinery.

Benefits: Durability, aesthetic appeal, and ability to withstand harsh environments.

Properties: High strength, excellent corrosion resistance, and heat resistance.

Applications: Medical devices, food processing equipment, marine applications, and industrial machinery.

Benefits: Durability, aesthetic appeal, and ability to withstand harsh environments.

Properties: High strength, excellent corrosion resistance, and heat resistance.

Applications: Medical devices, food processing equipment, marine applications, and industrial machinery.

Benefits: Durability, aesthetic appeal, and ability to withstand harsh environments.

Properties: High strength, excellent corrosion resistance, and heat resistance.

Applications: Medical devices, food processing equipment, marine applications, and industrial machinery.

Benefits: Durability, aesthetic appeal, and ability to withstand harsh environments.

H59

H62

Properties: Good machinability, corrosion resistance, and antimicrobial properties.

Applications: Plumbing fittings, electrical connectors, musical instruments, and decorative items.

Benefits: Attractive appearance, easy to machine, and excellent for applications requiring low friction.

Properties: Good machinability, corrosion resistance, and antimicrobial properties.

Applications: Plumbing fittings, electrical connectors, musical instruments, and decorative items.

Benefits: Attractive appearance, easy to machine, and excellent for applications requiring low friction.

T1

T2

T3

C11000

C12200

Properties: High electrical and thermal conductivity, ductility, and corrosion resistance.

Applications: Electrical wiring, heat exchangers, and plumbing.

Benefits: Superior conductivity, easy to form and solder, and resistance to corrosion.

Properties: High electrical and thermal conductivity, ductility, and corrosion resistance.

Applications: Electrical wiring, heat exchangers, and plumbing.

Benefits: Superior conductivity, easy to form and solder, and resistance to corrosion.

Properties: High electrical and thermal conductivity, ductility, and corrosion resistance.

Applications: Electrical wiring, heat exchangers, and plumbing.

Benefits: Superior conductivity, easy to form and solder, and resistance to corrosion.

Properties: High electrical and thermal conductivity, ductility, and corrosion resistance.

Applications: Electrical wiring, heat exchangers, and plumbing.

Benefits: Superior conductivity, easy to form and solder, and resistance to corrosion.

Properties: High electrical and thermal conductivity, ductility, and corrosion resistance.

Applications: Electrical wiring, heat exchangers, and plumbing.

Benefits: Superior conductivity, easy to form and solder, and resistance to corrosion.

Grade 2

Grade 4

Grade 5

Properties: High strength-to-weight ratio, excellent corrosion resistance, and biocompatibility.

Applications: Aerospace components, medical implants, and marine applications.

Benefits: Lightweight, strong, and able to withstand extreme temperatures and aggressive environments.

Properties: High strength-to-weight ratio, excellent corrosion resistance, and biocompatibility.

Applications: Aerospace components, medical implants, and marine applications.

Benefits: Lightweight, strong, and able to withstand extreme temperatures and aggressive environments.

Properties: High strength-to-weight ratio, excellent corrosion resistance, and biocompatibility.

Applications: Aerospace components, medical implants, and marine applications.

Benefits: Lightweight, strong, and able to withstand extreme temperatures and aggressive environments.

Fe 360 A

Fe 430 A

Properties: High tensile strength, hardness, and wear resistance.

Applications: Structural components, automotive parts, and machinery.

Benefits: Cost-effective, versatile, and can be heat-treated for enhanced properties.

Properties: High tensile strength, hardness, and wear resistance.

Applications: Structural components, automotive parts, and machinery.

Benefits: Cost-effective, versatile, and can be heat-treated for enhanced properties.

GCr6

GCr9

GCr15

Properties: High hardness, wear resistance, and ability to retain sharp edges.

Applications: Cutting tools, dies, and molds.

Benefits: Excellent for high-stress applications and extended tool life.

Properties: High hardness, wear resistance, and ability to retain sharp edges.

Applications: Cutting tools, dies, and molds.

Benefits: Excellent for high-stress applications and extended tool life.

Properties: High hardness, wear resistance, and ability to retain sharp edges.

Applications: Cutting tools, dies, and molds.

Benefits: Excellent for high-stress applications and extended tool life.

ABS

Nylon

PEEK

Delrin

Polycarbonate

PTFE

PVC

Polypropylene

Properties: Lightweight, impact-resistant, and easy to machine.

Applications: Consumer products, automotive parts, and electronic housings.

Benefits: Good chemical resistance, easy to paint and finish, and affordable.

Properties: High tensile strength, wear resistance, and low friction.

Applications: Gears, bearings, bushings, and structural components.

Benefits: Excellent fatigue resistance, good chemical resistance, and versatility in various applications.

Properties: High thermal stability, chemical resistance, and mechanical strength.

Applications: Aerospace, automotive, and medical devices.

Benefits: Suitable for high-performance applications, maintains properties at elevated temperatures.

Properties: Low friction, high stiffness, and excellent dimensional stability.

Applications: Precision parts like gears, bearings, and automotive components.

Benefits: Excellent machinability, good wear resistance, and low moisture absorption.

Properties: High impact resistance, optical clarity, and good dimensional stability.

Applications: Safety glasses, protective equipment, and electronic components.

Benefits: Lightweight, shatter-resistant, and suitable for applications requiring transparency.

Properties: Low friction, high chemical resistance, and thermal stability.

Applications: Seals, gaskets, and bearings in chemical processing.

Benefits: Non-stick properties, excellent for high-temperature applications, and resistant to a wide range of chemicals.

Properties: Good chemical resistance, lightweight, and durable.

Applications: Pipes, fittings, and electrical insulation.

Benefits: Cost-effective, versatile, and available in rigid and flexible forms.

Properties: Lightweight, good chemical resistance, and fatigue resistance.

Applications: Packaging, automotive parts, and consumer goods.

Benefits: Durable, recyclable, and suitable for a variety of applications.

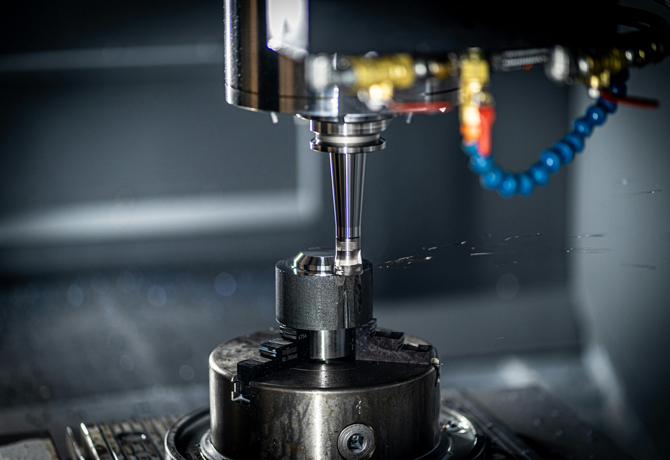

What is CNC Machining?

What is CNC Machining?

CNC (Computer Numerical Control) machining is a technology that utilizes computers to control machine tools for processing. Through precise numerical control programs, CNC machines can produce high-precision parts from materials such as metal and plastic. This technology is widely used in various fields, from prototype production to mass manufacturing.

How to choose materials suitable for CNC machining?

How to choose materials suitable for CNC machining?

Choosing suitable materials for CNC machining requires consideration of several factors:

What documents are required for CNC machining?

What documents are required for CNC machining?

To ensure machining accuracy, we typically require you to provide design drawings (in CAD format) and technical specifications of the parts, including dimensions, tolerances, surface treatments, and material requirements. If your parts have special requirements, you can also provide relevant testing standards and quality requirements.

What is the precision of CNC machining?

What is the precision of CNC machining?

Our CNC machined parts can achieve a minimum tolerance of ±0.003mm, making them highly suitable for the production of precision parts that meet most industrial standards.

What materials can CNC machining use?

What materials can CNC machining use?

CNC machining is widely applied to the processing of various materials, including metals (such as aluminum, stainless steel, titanium alloys), plastics (such as POM, ABS, nylon), and other composite materials. Different materials will be selected for different machining methods and tools based on their characteristics.

What is the typical lead time for CNC machining?

What is the typical lead time for CNC machining?

The lead time for CNC machining typically depends on the complexity of the parts and the quantity of the order. For small batches or single prototypes, we can deliver within a few days to a week. For large-scale production, the lead time will be extended accordingly. Specific timelines can be customized based on your needs.

How do you ensure the quality of CNC machining?

How do you ensure the quality of CNC machining?

We ensure the precision and consistency of each part through strict quality control processes. Each machining step undergoes precise measurement and inspection to ensure the final product meets design requirements. Additionally, our team conducts detailed quality checks before and after machining to ensure each part is defect-free.

How is the cost of CNC machining calculated?

How is the cost of CNC machining calculated?

The cost of CNC machining is typically influenced by several factors:

Is CNC machining suitable for mass production?

Is CNC machining suitable for mass production?

CNC machining is not only suitable for producing single prototype parts but is also very well-suited for mass production. With precise numerical control systems and efficient production processes, we can maintain consistency and high precision in mass production. This makes CNC machining an ideal choice for large-scale industrial manufacturing.

What are the advantages of CNC machining compared to traditional machining methods?

What are the advantages of CNC machining compared to traditional machining methods?

The greatest advantages of CNC machining over traditional manual machining are its high precision, efficiency, and consistency. With computer control, CNC can achieve precise machining of complex shapes and details while reducing manual operations and errors. Additionally, CNC machining can significantly improve production efficiency and shorten delivery times.