Home / Resources / Blog Articles / Intelligent Manufacturing: Future Trends in Enhancing Machining Services

Home / Resources / Blog Articles / Intelligent Manufacturing: Future Trends in Enhancing Machining Services February 14, 2025

February 14, 2025

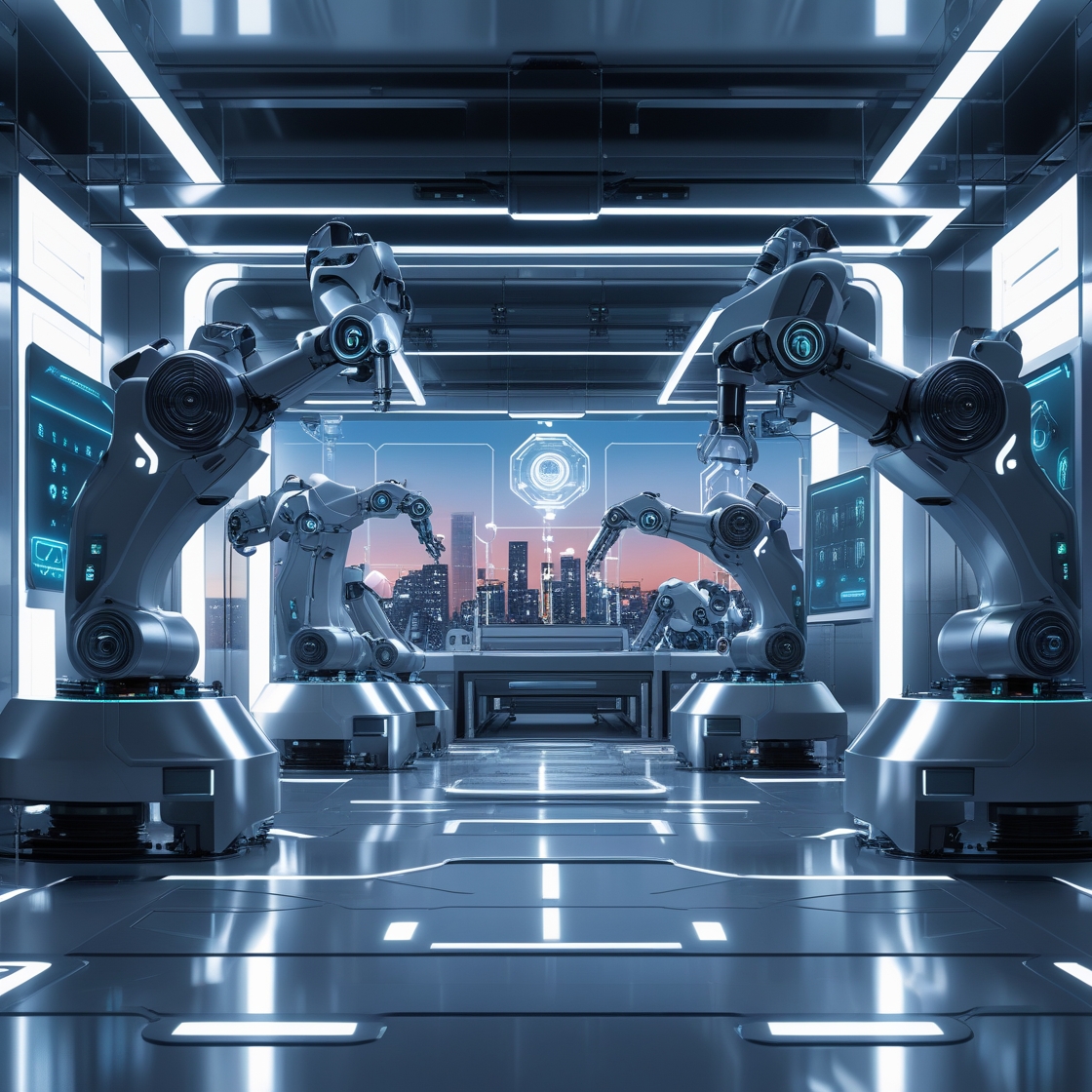

As the manufacturing industry continues to evolve towards greater efficiency, precision, and flexibility, intelligent manufacturing has become a key technology for enhancing production efficiency and quality. Particularly in the field of machining services, intelligent manufacturing not only automates and digitizes production processes but also significantly drives process optimization, precision enhancement, and maximization of resource utilization. This article explores the applications of intelligent manufacturing in the machining sector, including technologies such as automation equipment and data analysis, and analyzes its profound impact on production efficiency, product quality, and the future development of the industry.

Intelligent manufacturing refers to the use of information technology, automated control systems, artificial intelligence (AI), and big data to achieve high levels of automation, flexibility, and intelligence in production processes. Compared to traditional manufacturing, intelligent manufacturing relies not only on hardware improvements in machinery but also emphasizes system-wide collaborative optimization, data-driven decision-making, and intelligent operations.

1. Increased Automation: With the continuous advancement of robotics and automation equipment, intelligent manufacturing shows great potential in reducing human intervention and improving production efficiency. Robotic arms, automated feeding systems, and automatic inspection devices have become indispensable components in workshops.

2. Deepening Digital Transformation: Digitalization is the core support for intelligent manufacturing. Digital factories, virtual simulation technologies, and real-time monitoring systems help enterprises achieve comprehensive information management. These technologies can collect and analyze data in real-time, allowing for adjustments in production strategies.

3. Green Manufacturing: With rising environmental requirements, intelligent manufacturing places greater emphasis on energy conservation, emission reduction, resource recycling, and sustainable development, becoming an inevitable trend in the industrial sector.

In the machining field, the combination of automation and digitalization serves as the main driving force for enhancing production efficiency and quality.

Automation equipment in machining processes (such as automated machine tools, CNC machines, and robotic assembly systems) can efficiently execute production tasks, saving labor costs and increasing productivity. Automated equipment significantly reduces error rates in production through precise control and operation, ensuring product consistency and high precision.

For instance, CNC (Computer Numerical Control) systems have become standard in the machining industry. They can perform efficient and precise machining through digital control commands, accelerating production speed while ensuring the accuracy and consistency of each part.

The core of digitalization lies in the real-time collection and analysis of various data during production through sensors, intelligent control systems, and big data analytics. This data helps enterprises monitor production conditions, predict equipment failures, and optimize production processes based on real-time feedback.

- Predictive Maintenance: Leveraging big data and machine learning technologies, intelligent manufacturing can monitor equipment in real-time and predict potential failures. By detecting issues early, downtime is reduced, ensuring continuity in the production process.

- Process Optimization: In-depth analysis of production data enables companies to identify bottlenecks and process issues, allowing for targeted improvements. This data-driven optimization can significantly enhance production efficiency.

The advantages of intelligent technologies in enhancing production efficiency and quality are evident. The following aspects demonstrate how intelligent manufacturing drives transformation in machining services:

Through machine vision, AI, and robotics, the production processes in machining have become more automated. For example, in precision machining, intelligent workpiece inspection systems can monitor dimensional deviations in real-time and automatically adjust tool parameters to ensure that each workpiece meets precision requirements.

Intelligent manufacturing systems can automatically adjust production processes based on real-time data analysis, improving machining efficiency. For instance, intelligent tool management systems can automatically select the best tools and precisely set cutting speeds based on material types and thicknesses, eliminating errors from manual intervention and enhancing production stability and precision.

Intelligent production scheduling systems utilize AI and big data technologies to optimize resource allocation based on production demand, machine status, and process requirements. This scheduling capability can significantly shorten production cycles and improve resource utilization.

In the automotive industry, intelligent manufacturing has been widely adopted. For example, in the machining of engine components, automated assembly lines and robotic equipment work collaboratively to achieve efficient production and high-precision machining. The flexibility of robots allows production lines to adapt to diverse product demands, meeting the requirements for various engine component models.

In the aerospace sector, machining requires extremely high precision, and intelligent manufacturing technologies provide perfect solutions. Through the collaboration of intelligent CNC machines and automated inspection equipment, the production precision of critical components has significantly improved, while real-time data analysis ensures the quality and safety of the entire production process.

Intelligent manufacturing also shows tremendous potential in the medical device sector, especially in the machining of miniature parts. By utilizing high-precision machine tools and automated production lines, companies can produce high-precision medical device components at lower costs, ensuring product safety and reliability.

Despite the unprecedented efficiency and quality improvements brought about by intelligent manufacturing, several challenges remain:

As intelligent manufacturing becomes more widespread, establishing unified technical standards and ensuring the security and reliability of data are significant challenges faced by the industry. Particularly in big data analysis, protecting sensitive corporate information from leaks and ensuring the transparency and interpretability of AI algorithms are urgent issues that need to be addressed.

The advancement of intelligent manufacturing requires a large number of highly skilled technical personnel. However, the current shortage of related skilled workers severely restricts the comprehensive development of intelligent manufacturing. Companies must invest in training and attracting technical talent to ensure the successful implementation of intelligent manufacturing.

While intelligent manufacturing offers long-term benefits, the initial investment is often high. For some small and medium-sized enterprises, balancing cost control with technological upgrades presents another challenge.

The application of intelligent manufacturing in machining is transforming production methods and quality standards. Through the use of automation equipment, digital transformation, and big data analysis, companies can significantly enhance production efficiency, reduce costs, and ensure the stability of product quality. As technology continues to advance, intelligent manufacturing will play an increasingly important role in future machining services. At the same time, the industry must focus on continuous innovation in areas such as technological standardization, data security, and talent development to meet future challenges and seize greater opportunities in intelligent manufacturing.